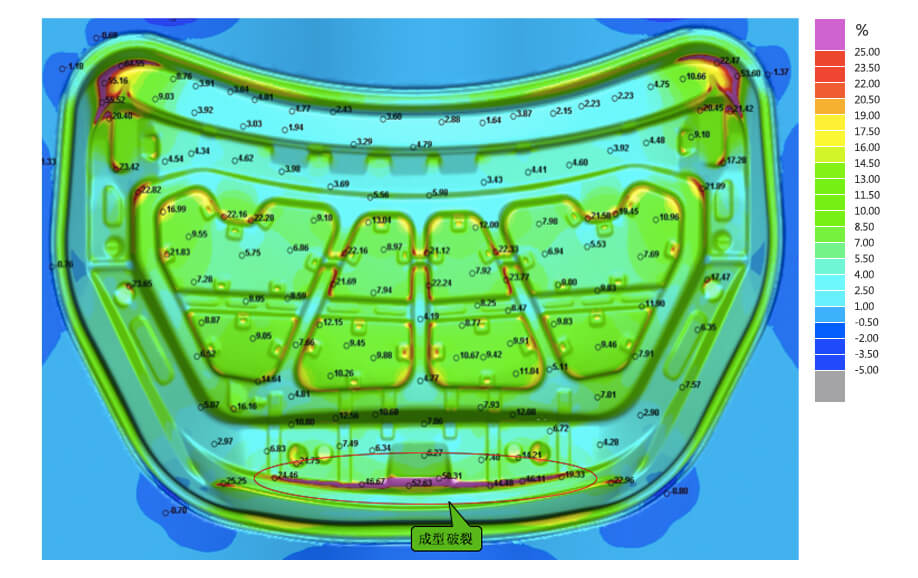

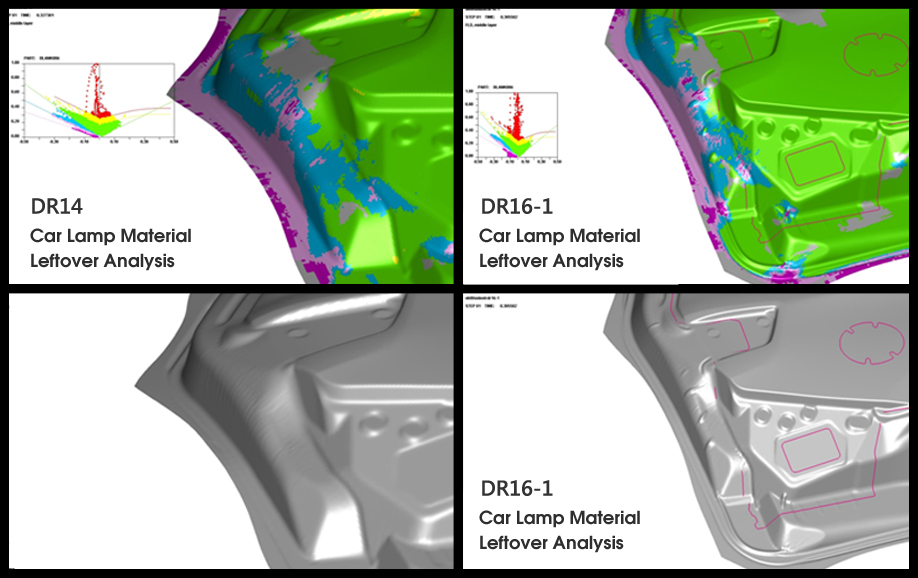

Computer Aided Engineering – CAE

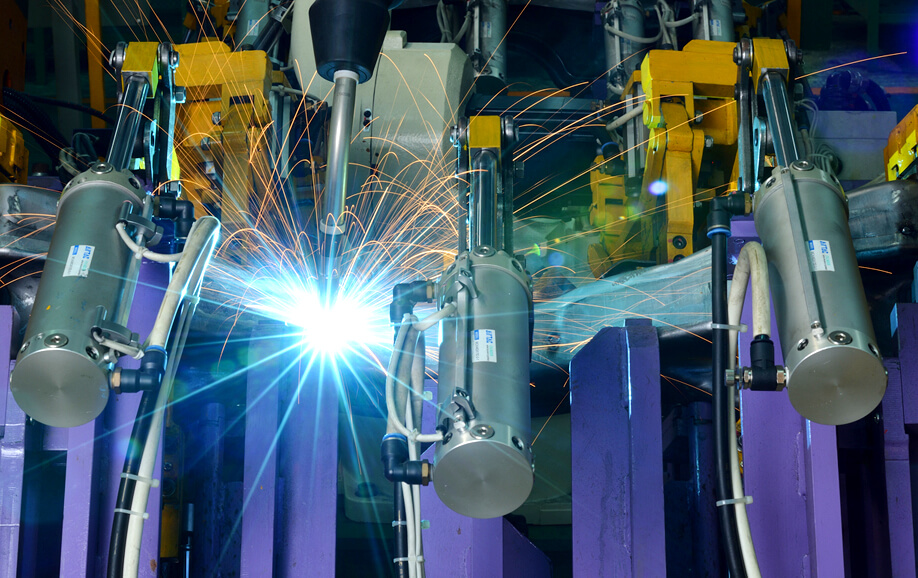

Jui Li adopts computerized part formability analysis to find design and quality related issues in the early design stages. We make use of risk control analysis in the early developing stages, analyzing formability and deformation factors.

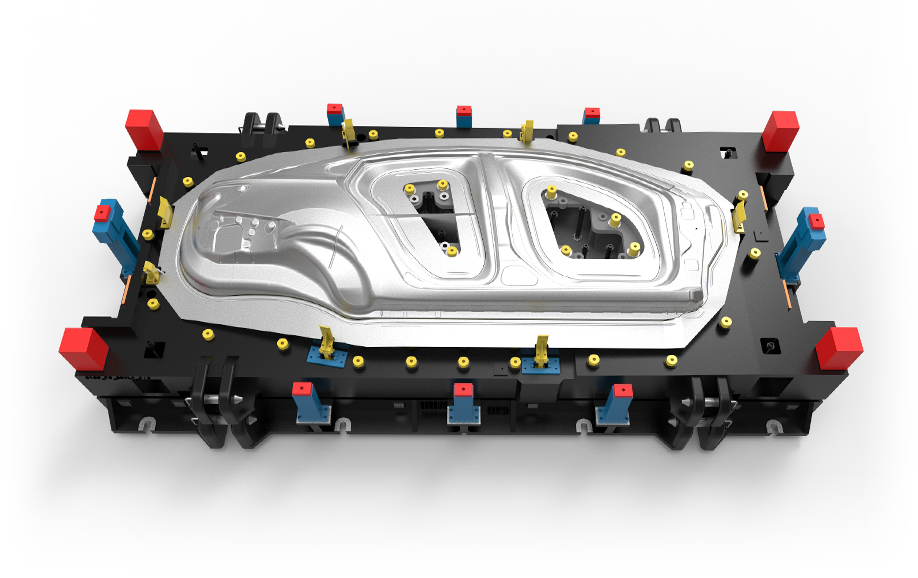

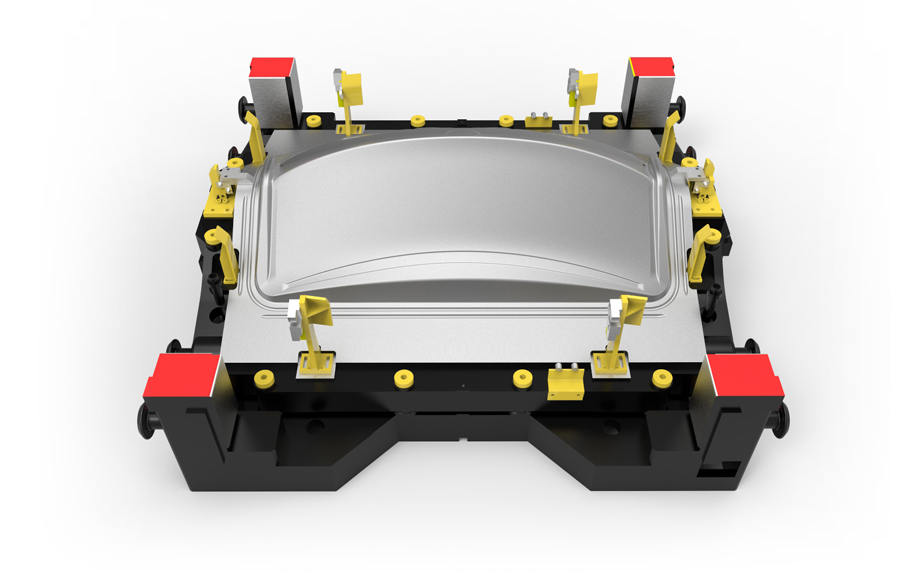

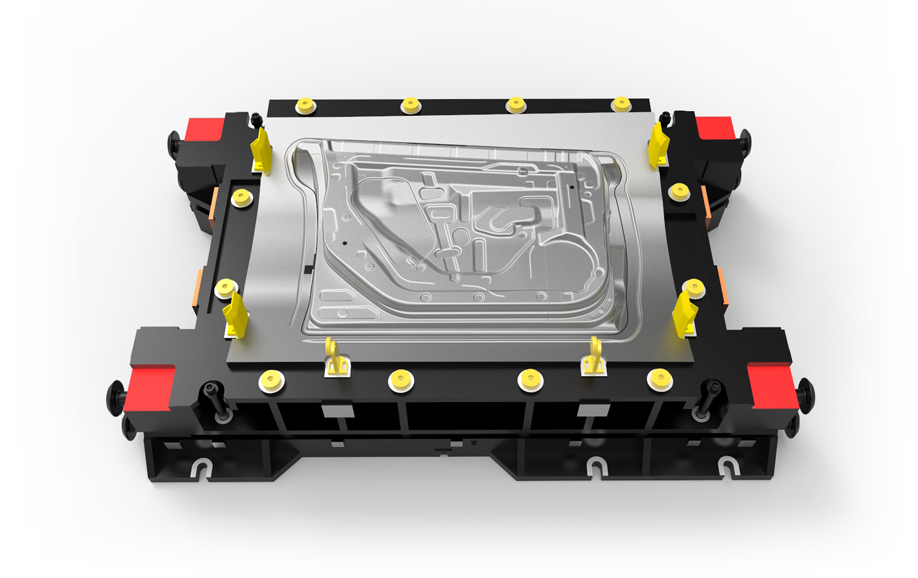

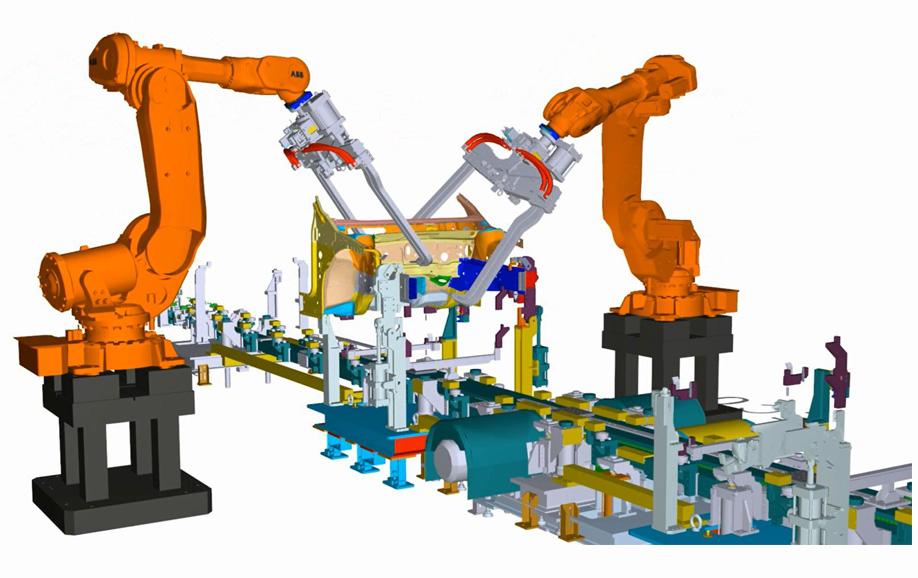

Die Design

JuiLi makes use of Catia and UG software as design platforms. In a 3D environment we have accomplished the development of dies, checking fixtures, and JIGs. With 3D die design technology, we can offer customers with highly stable die products.

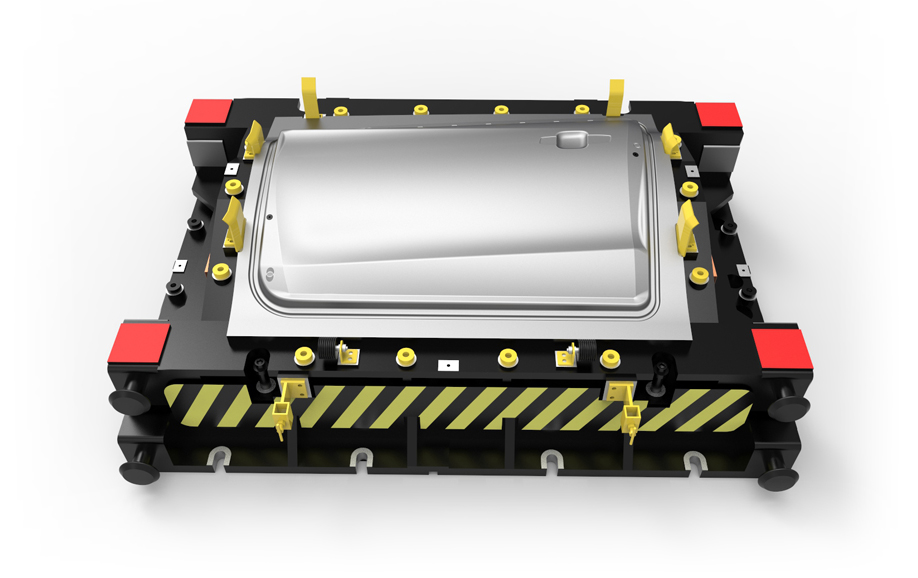

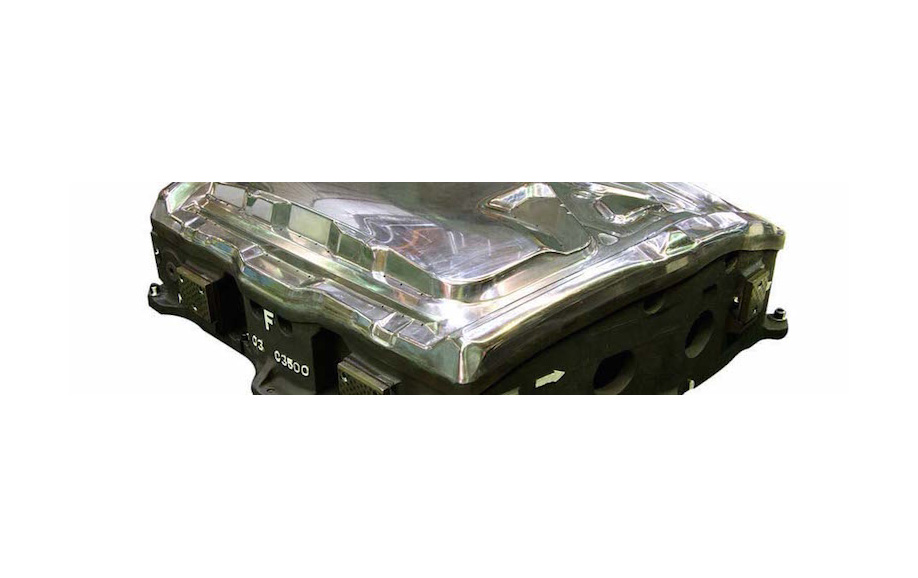

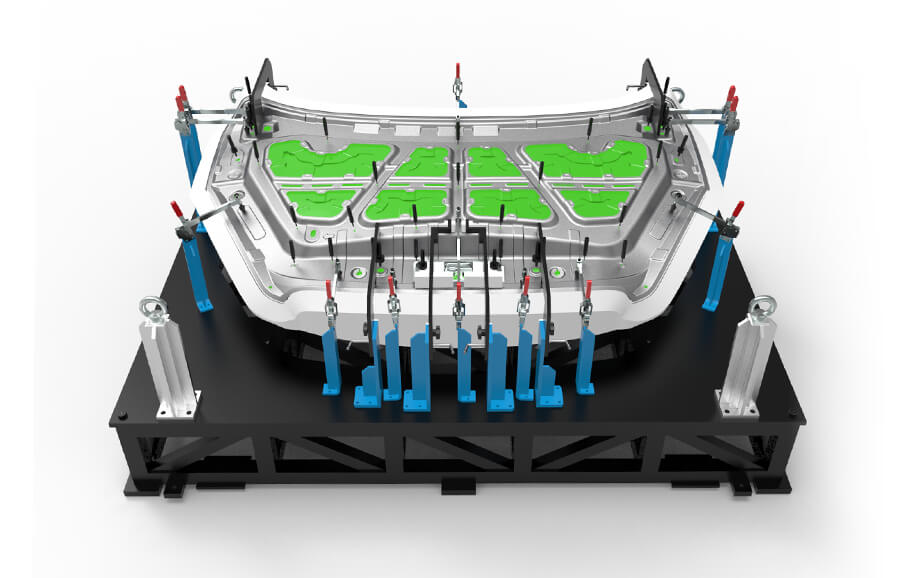

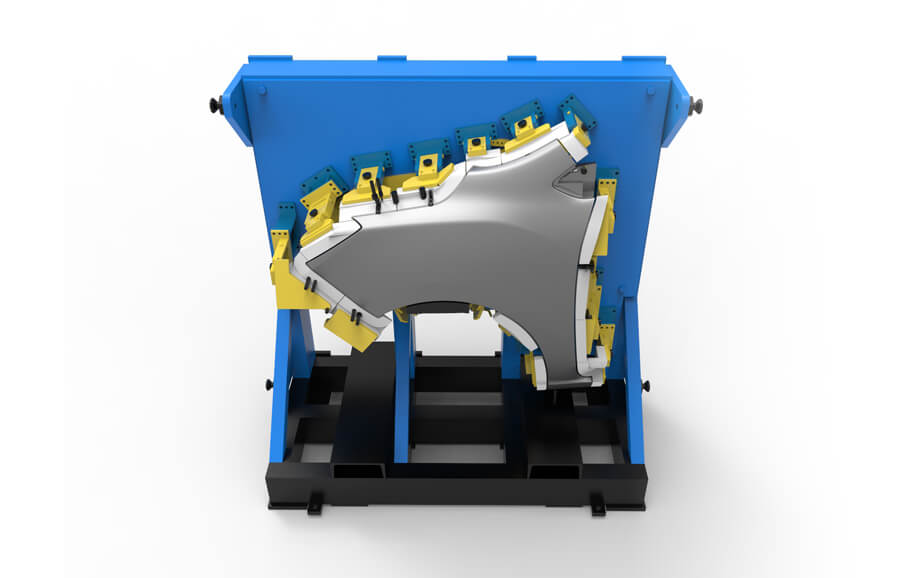

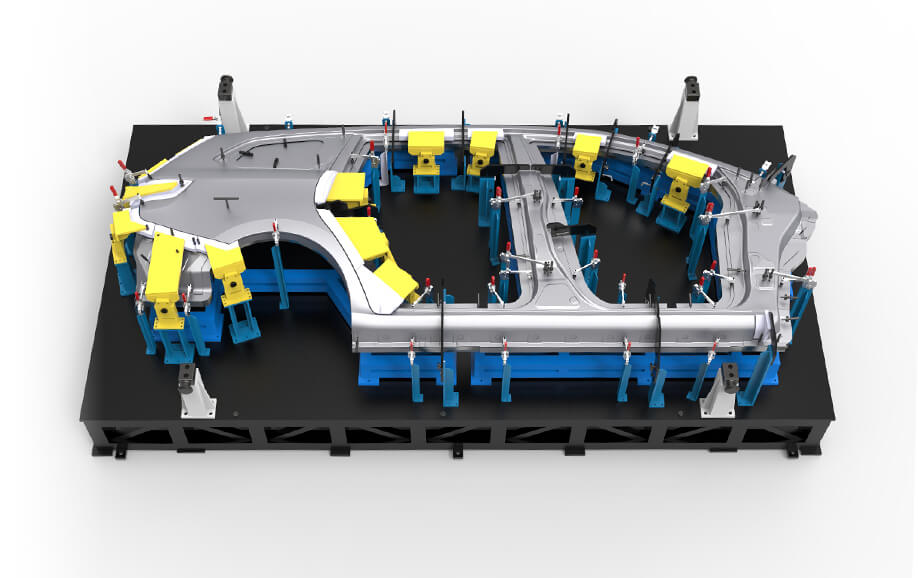

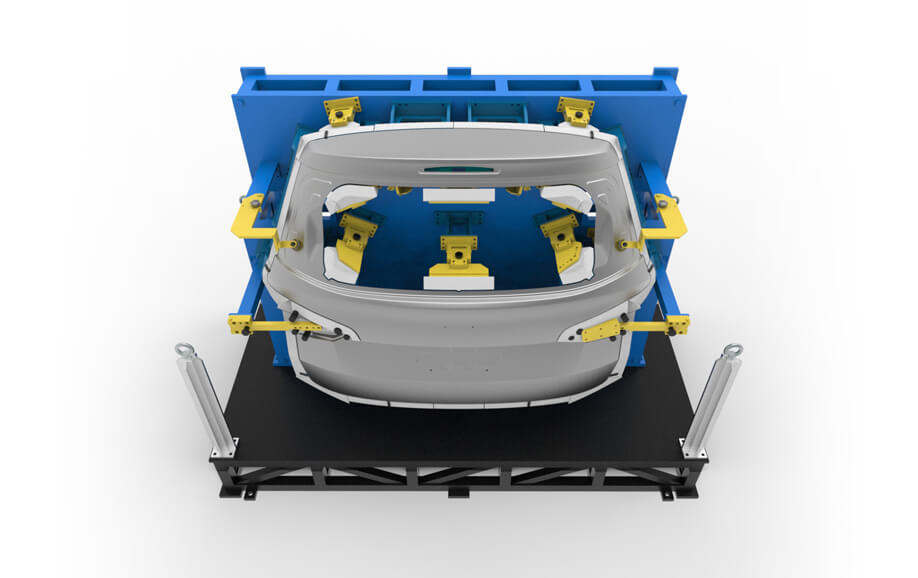

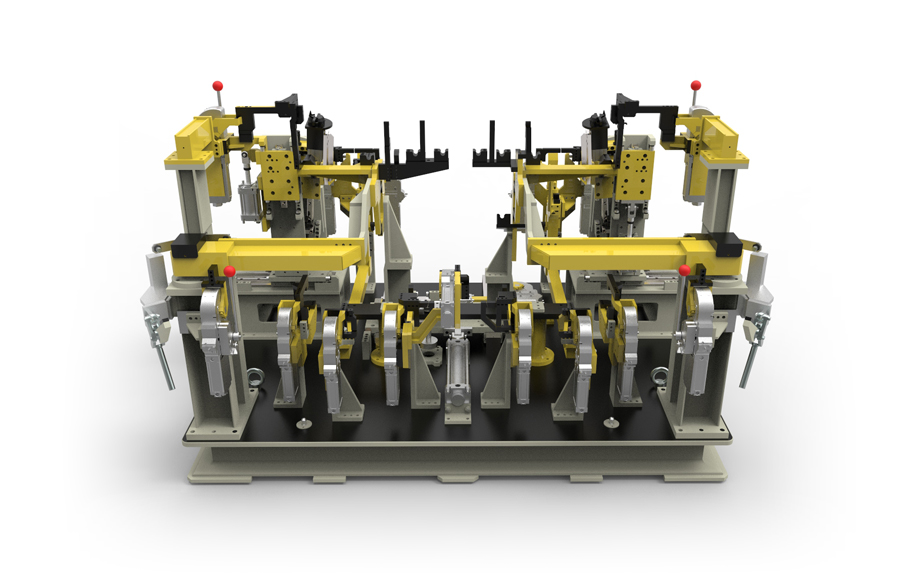

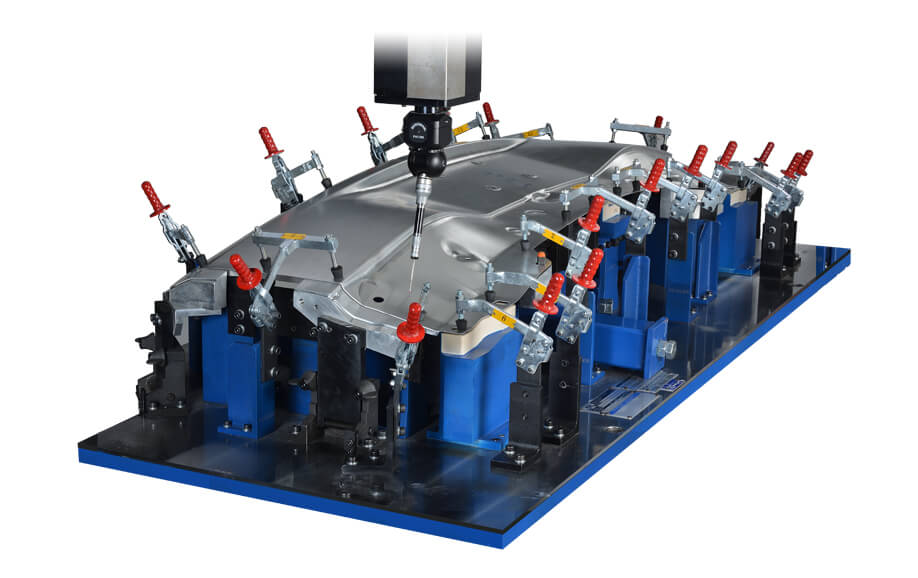

Checking Fixture & Jig Design and Manufacturing

We have over three decades of experience in tooling. Our specialties are BIW, Under Body Parts, Chassis - we provide the comprehensive assembly solution.

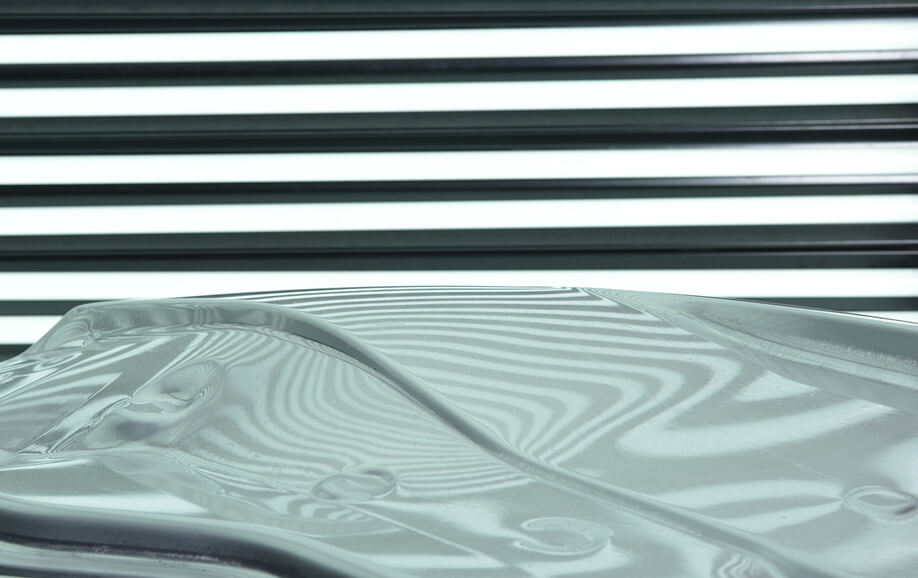

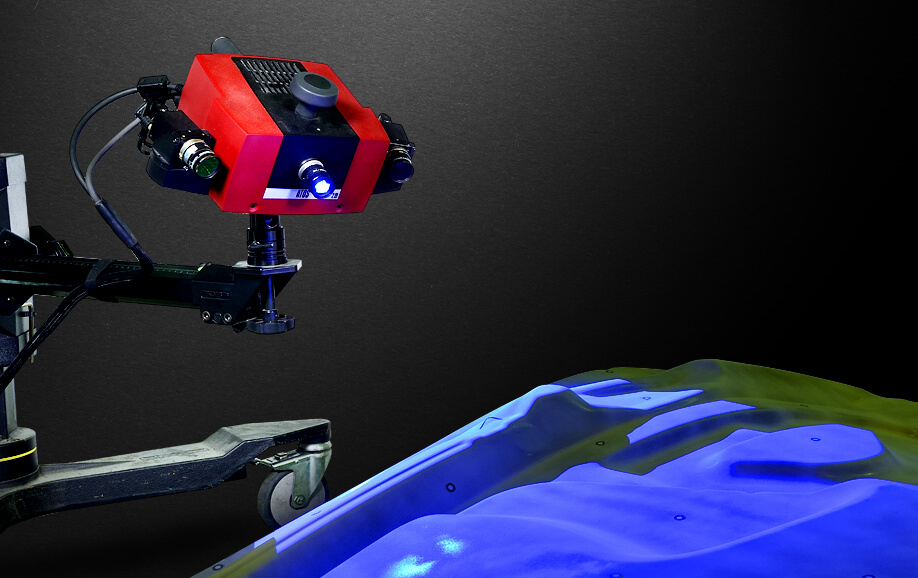

Accuracy Inspection and Exterior Quality Determination

JuiLi imported DEA large scale CMM inspection equipment, as well as an Atos computer aided inspection system, which can compare die and parts parameters, shortening the R&D procedure. Spectrum analysis is utilized to modify the accuracy of parts and dies.